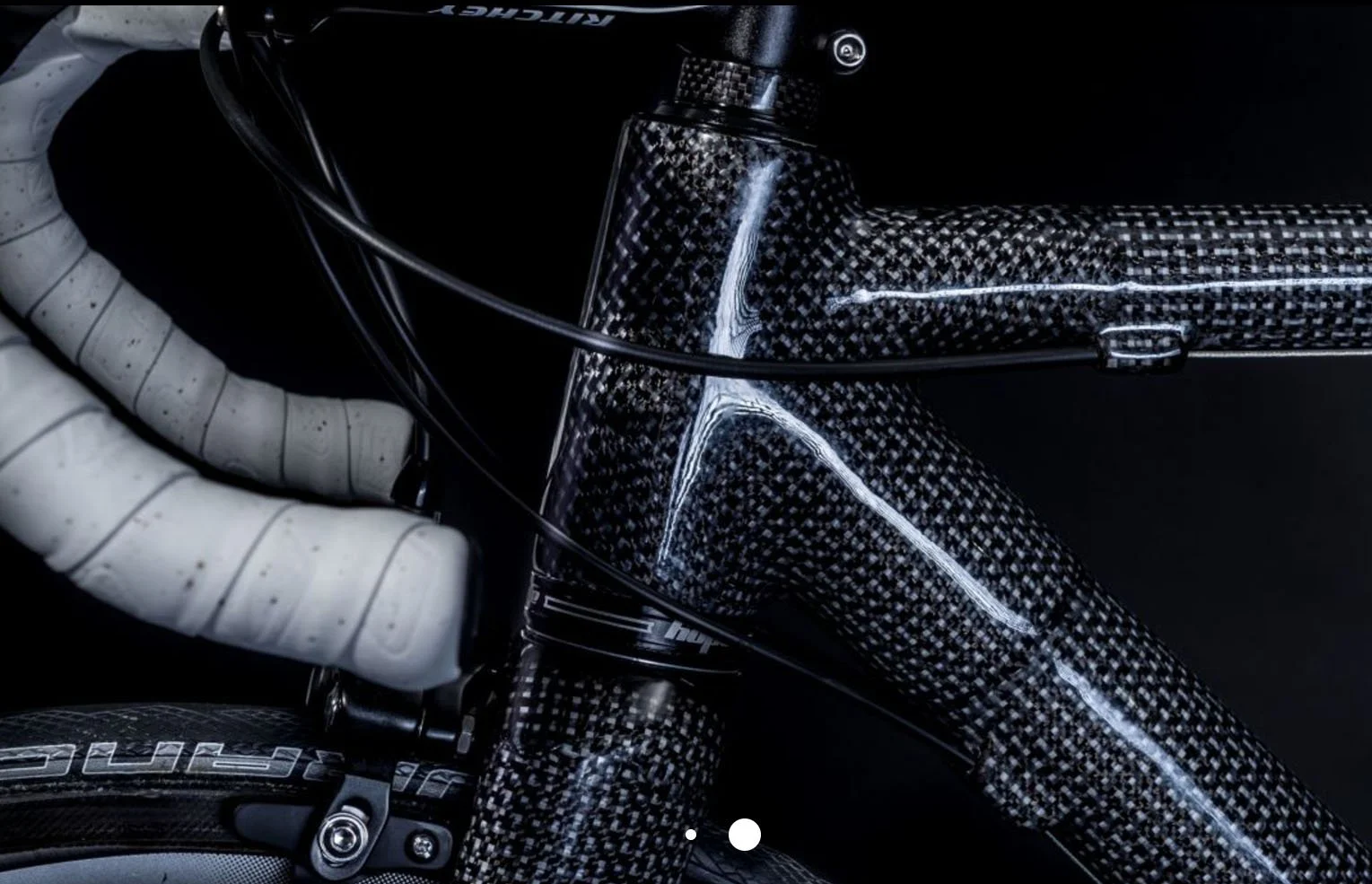

Carbon Fiber Sucks!

Controversial opinion, I know.

Carbon Fiber is incredible for cyclists, Lightweight Experimental Aircraft, and Formula 1, but the idea of using carbon fiber for protective parts is, sub optimal. Sexy, Lightweight? Yes. Protective? Not exactly.

Most people believe that Carbon fiber is superior for every application. But, when the goal is protection from scratches, dents, and everyday-trials-impacts, durable purpose-built plastics are the better material choice.

Plastic Absorbs Impact. Impact Breaks Carbon Fiber.

The primary advantage high-density thermoplastics have over carbon fiber is how they respond to impact. These plastics are energy-absorbing, they deform under impact, dissipating force rather than concentrating it. What we call a “dent” in plastic is actually a sign of protection working as intended. Plastic yields and deforms to absorb energy. Carbon fiber does not.

So, why would you choose carbon fiber over engineered plastics? In applications where rigidity to weight matters, like bicycles carbon fiber is still king. Carbon fiber is built for stiffness and tensile strength, not for taking hits and soaking up energy. BASH it, and it usually cracks, splinters, frays — with fibers poking out — instead of denting or flexing like plastic. That "minor ding" you see on the surface? It often means hidden cracks or delamination, which compromises strength and its ability to protect what matters.

This difference makes plastic more reliable in situations where repeated bumps, drops, and smashes are expected. COUGH Practicing trials.

Plastic Resists Scratches Better in Real-World Use

The surface of carbon fiber is protected by a thin resin layer that scratches easily. Once scratched, the damage is immediately visible and often permanent. Deep scratches can lead to fraying, which compromises structural integrity. Not to mention, have you ever been washing your bike, only to get small shards of carbon fibers lodged in your skin? LAME.

Plastics are more forgiving, engineered for abrasion resistance, cold or UV exposure, etc. Texturing on plastic can help hide wear, allowing plastic parts to maintain their appearance over time.

TLDR;

For impact protection, like fork guards and engine covers, purpose-built plastics offer superior durability, damage tolerance, and ease of maintenance. Carbon fiber remains The KING for lightweight structural performance, but its brittleness and surface vulnerability make it a poor choice for impact protection.

Carbon Fiber

Pros

Exceptional stiffness-to-weight ratio

Carbon fiber offers outstanding rigidity and strength for structural applications where weight savings are critical.High tensile strength

Performs extremely well under controlled loads aligned with fiber orientation.Premium appearance and perception

Often valued for its visual appeal and association with high-performance industries.Dimensional stability under load

Maintains shape and stiffness when stresses remain within design limits.

Cons

Poor impact tolerance

Carbon fiber tends to crack, delaminate, or splinter under impact rather than absorb energy.Brittle failure mode

Carbon fiber does not dent; it fails abruptly, often with hidden internal damage.Highly sensitive to impact direction

Performance depends on fiber orientation, making it unpredictable in uncontrolled environments.Expensive to repair or replace

Repairs require specialized skills and are often cost-prohibitive.Overengineered for protective roles

Its strengths are unnecessary—and sometimes counterproductive—when the goal is surface and impact protection.